DEFINITION

HSS saw blade also called cold saw, which is designed to cut metal material to transfer the heat generated by cutting to the chips created by the circular saw blade, allowing both the blade and material being cut to remain cool. High speed steel (HSS) saw blade is a kind of blade composed of a certain amount of carbon (C), tungsten (W), molybdenum (Mo), chromium (Cr), vanadium (V), etc. High speed steel blanks, the semi-finished products have high hardness after cutting, forging, annealing, quenching and grinding procedures. Due to the high cutting temperature, however, hardness is still not significantly reduced when it reaches 600 °C or above. The cutting speed can reach more than 60 meters per minute. That the reasons why named high speed steel (HSS) saw blade.

APPLICATION

HSS circular saw blades are ideal for sawing or cutting off a wide variety of sizes and shapes such as extrusions, tubes, pipes, sheets, plates and some bar stock, including:

medium to high tensile carbon steel

- sticky materials

- thin walled steel tubes & profiles

- non-alloy tool steel, etc.

TOOTH FORMS

The following specifications are given an idea of the most commonly requested HSS Saw Blade tooth forms. Different tooth forms will get different cutting performance, a correct tooth form will improve your production and cut costs.

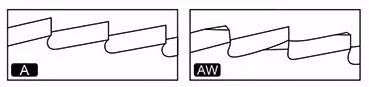

Tooth Form “A” & “AW”

For thin metal slitting saw blade with a tooth pitch up to approx. 3.0mm. Advisable for brass. Tooth form “A” is suitable for slotting materials. All teeth of tooth form “AW” are beveled alternatively.

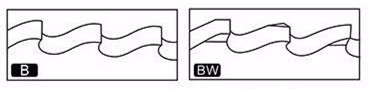

Tooth Form “B” & “BW”

Suitable for cutting tubes and profiles made of steel or non-ferrous metals. Tooth form “B” is specialized in cutting very thin-walled pipes and profiles. All teeth of tooth form “BW” are beveled alternatively.

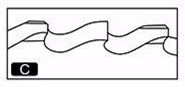

Tooth Form “HZ”

This tooth is also known as form “C”. Teeth are ground according to the roughing and finishing tooth system. A tooth pair is consising of one roughing tooth (1/3 cutting width) and one finishing tooth (2×1/3 cutting width). According to the triple chip geometry the roughing tooth is approx. 0.2~0.3mm higher compared with the finishing tooth. Tooth form “HZ” is suitable for cutting solid materials.

Tooth Form “CB”

Chipbreaker tooth form is most effective for tube and profile cutting. It minimizes burr formation even at high cutting speed. It requires a stronger motor and allows the highest speeds. At high speeds the tube walls should not be too thin.

CHARACTERISTICS

HSS saw blade can be sharpened with blade sharpening machine or CNC grind machine, which will improve its production efficiency and reduce costs.

The popularity of HSS saw blades is increasing because of the technological advancements in grinding machines.

HSS saw blades consistently produce the lowest cost per cut among all sawing methods.

USAGE INSTRUCTIONS

In order to perform HSS saw blade at its best, it must be used in strict accordance with the following instructions:

Different saw blades have different thickness, teeth forms or teeth number, so try to use them according to their application fields;

The size and shape accuracy of the spindle and the clamp of the equipment have a great influence on the cutting performance. Check and adjust before installing the saw blade. In particular, eliminate the displacement and slippage caused by the contact surface between the splint and the saw blade;

Pay more attention to the working condition of HSS saw blade at any time, if any unusual occurred, such as vibration, humming, must be stopped and adjusted in time, and repaired in time to maintain its best performance;

Do not change its original angle while repair HSS saw blade, and avoid rapid temperature change on teeth, it’s better to find professional repair places to do grinding.

Vertically hung the saw blades that are not used, avoid flat lay for a long time, do not be placed HSS saw blade on the object stack. The teeth should be protected from a collision.

APPLICABLE MACHINERY

High-speed steel saw blades are widely applied on below machinery:

automatic hydraulic pipe cutting machine

semi-automatic hydraulic pipe cutting machine

metal circular saw machine

pipe cutting machine

pipe processing machinery

sawing machine

milling machine, etc.