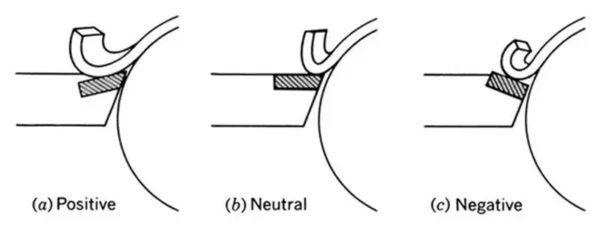

No matter what kind of processing is used, the tool has three main angles: rake angle, plunge angle and relief angle. Its functions are as follows:

① Rake Angle

Rake angle is a parameter used in various cutting and machining processes, describing the angle of the cutting face relative to the work, which affects cutting force, cutting edge strength and chip flow characteristics.

Giving a positive rake angle to an HSS saw blade reduces the forces on the tool, reduces the power required and make the process economical.

Generally, positive rake angles:

■ Make the tool more sharp and pointed. This reduces the strength of the tool, as the small included angle in the tip may cause it to chip away.

■ Reduce cutting forces and power requirements.

■ Helps in the formation of continuous chips in ductile materials.

■ Can help avoid the formation of a built-up edge

② Pitch angle

The angle at which a propeller, rotor, or turbine blade is set with respect to the plane of rotation, which controls the direction of cutting power, effectively thins chips and protects the weakest cutting edge.