We Received an Inquiry From Mr. Hansen

We received an inquiry from Mr. Hansen dated Jan 28th, 2019. He asked whether we offered TCT circular saw blade for wood in size 160, 165, 300, 315, 400mm.

Mr. Hansen from Northern Europe, after carefully checking his website, found he is dealing with tools business locally. We have no idea how many pieces of TCT blades he sells annually. After discussing with my colleagues, we finished a quote based on our standard MOQ (minimum order quantity), 160 and 165 in 200pcs, 300, 315 and 400 in 100pcs, and sent him in 5 hours.

HAOJING has a rule, any inquiries will be replied within 24 hours. Customer first is always our main focus, we supply quality services.

Preparing Samples

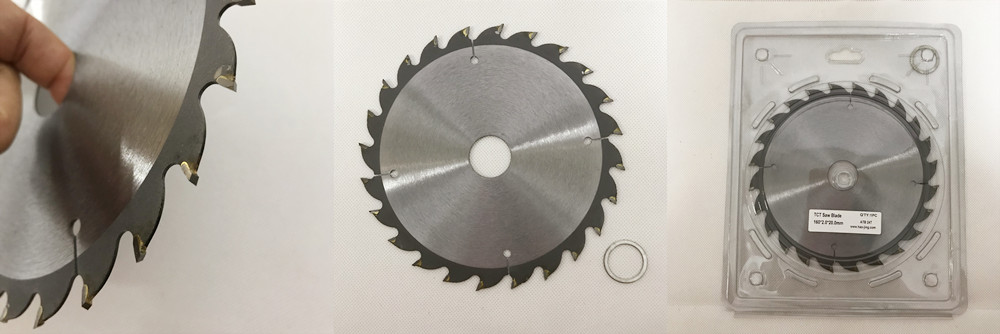

Before sending samples, we carefully took photos and kept another 2pcs in our warehouse marked Mr. Hansen for backup. The detailed photos were combined and sent to him for reference. Today was last day of January.

Samples were well packed and we added packing list inside.

On February 8th, it shown that parcel arrived. Mr. Hansen told me that he would test them in 1-2 weeks.

After Chinese Spring Festival, it was already Feb. 18th, I hope Mr. Hansen has received comments for our TCT blades. He replied me on Feb. 22th, but never mentioned any feedback about TCT blades testing. He just gave me orders. That is a good sign, sample quality is proved!

He confirmed me an order as followed:

Ø 160×2.3x20mm 24T 200PCS

Ø 160×2.3x20mm 48T 200PCS

Ø 165×2.3x20mm 24T 200PCS

Ø 165×2.3x20mm 48T 200PCS

What Behind Mr. Hansen’s Order

There are some problems while dealing with his order:

1. 20mm bore size has to be customized, standard is 25.4mm, 800pcs is not a big amount for customize service, which will increase some costs.

2. He required blue and yellow spray painting on blade bodies. Spray painting now seldom applied, as it is quite polluted. Now, most of TCT blades are using laser printing. We have to discuss with management and workshop.

3. The blister packaging: the standard packing for TCT blades is white paper box. We checked with blister package supplier, they informed 800pcs was far less than their MOQ.

4. Inside paper work: The paper work inside the blister package has to be cut in some certain round or special shaped holes, with two-sided printing. Generally, printing supplier always asked for 10,000 pcs as their MOQ.

After discuss and analysis all these issues, finally, we found the prices was hard to cover all these customized services of a 800pcs order. However, we did not mention Mr. Hansen all the details. We have to keep our promise as previously quote, finally our team decided that we would absorb all the extra costs, and make sure every piece of blade would be much better than sample.

After the call, he finished the deposit and sent us the payment copy on March 4th.

We started his order immediately, but found it was not as smoothly as we thought. The bore size, blister packaging, paper works, spray painting, all of these has to be confirmed with our workshop one by one, and we have to order suitable blister packaging and paper works all by ourselves. The charges were really costly compare to the MOQ supply.

In order to cut some costs for our company, we had to source the blister packaging and paper works for 5-10 suppliers, to check which one was cost-effective, more reliable, the most important, high quality.

Finally, we settled down, and confirmed the design again and again with suppliers. It took us much more times to finish.

During the manufacture, I informed Mr. Hansen, the lead time would be delayed, asked him for understanding. Luckily, Mr. Hansen is really kind and understanding our position. We really appreciated for his understanding.

At the end of April, Mr. Hansen asked when his order would be ready, as he had a container in China to be shipped after May Holiday. I checked with workshop, they were waiting for spray-painting procedure. I had to push workers to proceed, but I fully aware that haste may cause problems easily. I have to find a balance between my customer and workshop, I don’t want to break the balance, or someone will fall down.

At the end of April, Mr. Hansen asked when his order would be ready, as he had a container in China to be shipped after May Holiday. I checked with workshop, they were waiting for spray-painting procedure. I had to push workers to proceed, but I fully aware that haste may cause problems easily. I have to find a balance between my customer and workshop, I don’t want to break the balance, or someone will fall down.

Spray painting was finished. We took one piece for testing, to ensure its cutting performance and quality.

1.TCT circular saw blade is stable to cut plywood board

2.The cutting edge of plywood are clean

3.After cutting, testing blade are still in good quality

You could check the testing video here:

In order to make sure they finished before May Day holiday, me and my colleague had to go workshop and packed with workers together. Blister packing with paper work procedure would require more times to finish each piece. We finally finished the packing at 9:00 pm, everyone felt exhausted.

Finally, we finished the outer packing. 8 cartons of 240KGS were waiting for delivering car.

Tips: How to Grind the TCT Saw Blades for Woodworking to Achieve the Best Results

The quality of woodworking saw blades is good or bad, and the density has an important relationship with the quality of processed products. Proper selection of good quality saw blades for product processing has a major impact on the quality and effectiveness of the product. In addition, the choice of a good saw blade not only saves processing time, reduces the waste of resources, but also makes it easy to complete tasks and save energy. The saw blade can be selected according to the type of product to be cut to find the most suitable saw blade for processing.

Woodworking saw blades are TCT saw blades. When grinding, you must find a place to grind or return to the factory for grinding. Do not grind the teeth manually, as this may cause the saw blade to be damaged or unusable.

The TCT saw blade grinding machine first needs to use a professional saw blade grinding machine. In addition to strict requirements on the grinding wheel, motor, table, etc., it also needs to be equipped with a suitable grinding fluid (cutting fluid). The main function is to carry out the alloy cutter head. Cooling, while improving the flatness of the cutting surface, improve the grinding effect.

In addition, depending on the needs of the saw blade, a number of factors must be considered in the design, the most important of which is the angle of the blade teeth.