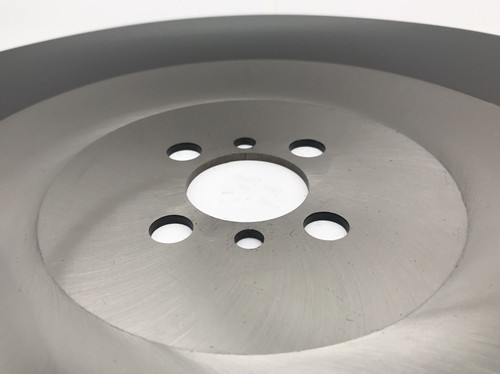

SILVER FOX, P.V.D multi-layer coating with a thickness of 2.5 microns, opaque grey colored. The particular composition and the innovative mix of noble elements developed by our R&D achieves a hardness which is higher than 3.650 Vickers (HV 0.05), unattained by any other coating. It’s suggested for cutting high alloy steels up to 1000 N/mm2, stainless steel and all material developing high thermal energy.

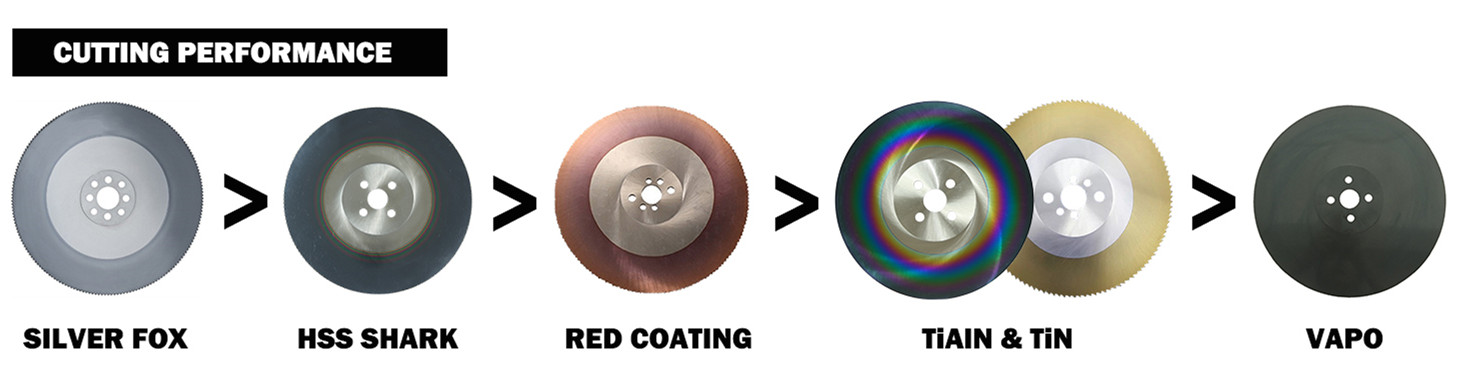

Advantages compare with other coatings

● Very tenacious and very resistant to high temperatures.

● Guarantee long-life when using blades at high speed.

● Highly recommended for blades to work with critical cutting parameters on high performance machines.

COATING FEATURES

| VAPO | LEOPARD | TIALN | RED | HSS SHARK | SILVER FOX | |

|---|---|---|---|---|---|---|

| Hardness HV (0.05) | 900 | 2480 | 2800 | 3200 | 3400 | 3650 |

| Friction Coefficient | 0.65 | 0.50 | 0.50 | 0.20 | 0.55 | 0.45 |

| Thickness (µm) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Maximum Working Temperature | 400°C | 450°C | 450°C | 450°C | 560°C | 560°C |

Coatings carefully designed for each specific cutting application

Our surface coating department is equipped with machines that use the latest technology in the field of Physical Vapour Deposition. Technical department and research centres make machine manufacturers and end-users productivity. Our engineers to recommend for each specific application the tool which provides the highest performance in terms of speed, feed rate and durability, all of which guarantee the lowest possible cutting cost.

HSS SAW BLADE COATING Circular saws are tools that require specific solutions to obtain the best results. It is not enough to guarantee the excellent quality and correct adherence of the coated surface. Still, it is also essential to keep unmodified the technical features, dimensions and cutting proprieties of the circular saw. All our HSS saw blades are coated to achieve the best cutting performance.

COATING CHOICE The choice of the coating depends on different parameters. It is not always easy to keep all of these in mind when choosing. The most important elements that influence the choice of coating are:

● The material to be cut

● The stiffness of the cut-off machine

● The quality and the quantity of the cooling agent

● The clamping stiffness of the piece to be cut

In the following chart, we would like to give an indication of the results obtained by our engineers with the most common materials.

| MATERIAL TO BE CUT | RECOMMENDED COATINGS |

|---|---|

| Low-alloy steel 400-600 N/mm2 | VAPO, LEPARD |

| Medium hard alloy steel 700-900 N/mm2 | TIALN, RED |

| Hard steel 900-1000 N/mm2 | HSS SHARK, SILVER FOX |

| Stainless steel | HSS SHARK, SILVER FOX |

| Cast iron | HSS SHARK |

| Inconel | HSS SHARK, SILVER FOX |

| Copper | LEPARD, RED |

| Bronze | LEPARD, RED |

| Brass | LEPARD, RED |