1. Suitable machine:

(1). Full-automatic cutting machine (with good performance, low cut cost and high efficiency.)

(2). Half-automatic and manual machine (can achieve the best cutting service life and can be applied for complex cutting situations)

2. Lubricant system

(1). Spray oil

(2). Emulsion

3. Cutting material

(1). High tensile strength material<1200N/mm2

(2). All stainless steel for tube and solid section

(3). Tool steel, bearing steel, special alloy steel

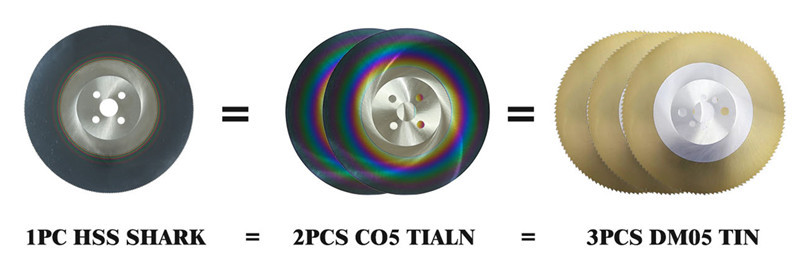

4. Introduction of coating

HSS SHARK is used for cutting high tensile strength material and stainless steel. It has a low friction coefficient, very high oxidation temperature and extremely low thermal conductivity. This coating has a quite binding force: if the coolant is not enough, it can still achieve good cutting performance with a fast cut.