What is HSS SHARK?

The SHARK saw blade uses materials accord with European standard. The sophisticated PVD coating treated SHARK saw blade has a dark grey or black layer, with high wear protection and achieves a very low friction coefficient. It is a cost-efficient solution for productive cutting.

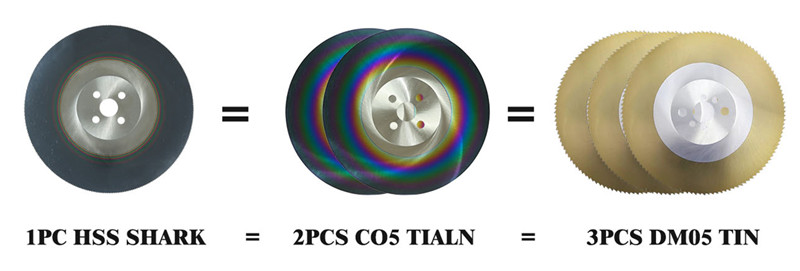

SHARK allows a higher cutting speed than a TiAlN treated saw blade while cutting tubes or pipes on manual and semi-automatic sawing machines. SHARK is also very suitable for cutting stainless steel tubes and profies.

Advantages Compare With Similar Blades

● Higher blade life

● Better wear protection

● Higher production output

● Lower cost per cut

● Ideal for cutting both structural steel and stainless

HSS SHARK Applications

| APPLICATIONS | ■ All applications like tubes, pipes, profiles. ■ Standard stainless (exclusive of 201 series) ■ Non alloy tool steel ■ Structural steel ■ Copper, brass |

|---|---|

| MACHINES | Manual, semi-automatic, automatic |

Available HSS SHARK Saw Blades

| Series | D (mm) | B (mm) | d (mm) | Z |

|---|---|---|---|---|

| HSS-SHARK | 250 | 1.2/1.6/2.0 | 32/40 | A/AW/B/BW |

| HSS-SHARK | 275 | 1.2/1.6/2.0 | 32/40 | A/AW/B/BW |

| HSS-SHARK | 300 | 1.2/1.6/2.0/2.5 | 32/40 | A/AW/B/BW |

| HSS-SHARK | 315 | 2.0/2.5 | 32/40 | A/AW/B/BW |

| HSS-SHARK | 325 | 2.0/2.5 | 32/40 | A/AW/B/BW |

| HSS-SHARK | 350 | 2.0/2.5 | 32/40 | A/AW/B/BW |

| HSS-SHARK | 375 | 2.0/2.5 | 32/40 | A/AW/B/BW |

| HSS-SHARK | 400 | 2.0/2.5/3.0 | 32/40 | A/AW/B/BW |

HSS SHARK Cuts Stainless Steel