Test Brief Introduction

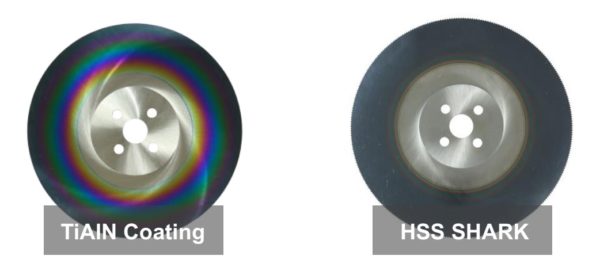

Get to know more about the relationship between HSS saw blade PVD coating and cutting performance. HSS SHARK highly improves cutting performance.

Conditions

● Testing date: July 22, 2019 ~ July 23, 2019

● Blade specification: 325×2.5x32mm 240T

● Cutting material: stainless steel 436

● Machine: hydraulic vertical pipe-cutting machine

Objective

How HSS saw blade PVD coating get closely involved with cutting performance?

Test Blade Specifications

|

Size details |

325×2.5x32mm |

|---|---|

|

Teeth details |

240T |

|

PVD coating |

HSS SHARK series (previous is TiAlN coating) |

|

Teeth grinding details |

Customer standard grinding angle is 13/18, R0.28; sharpening speed is |

Cutting Material Specifications

|

Pipe material |

Stainless steel 436 |

|---|---|

|

Pipe size details |

Diameter 65mm, wall thickness 1.2mm |

Machine Specifications

|

Machine |

Hydraulic vertical pipe-cutting machine |

|---|---|

|

Brand |

LONGXIN 355 |

|

Test Number |

Test Line 1 |

|

Cutting Time |

9s per cut |

Cutting Data

|

Feedback on site |

Skilled worker on site informed it could generally finish 700~800 cuts, |

|---|---|

|

Replace |

Replace a new or do sharpening when burrs happened in the wall of the |

|

Sharpening time |

Service time |

Sharpening data |

|---|---|---|

|

1st sharpening |

700 cuts (TiAlN coating) |

A |

|

2nd sharpening |

1300 cuts (HSS SHARK) |

A |

|

3rd sharpening |

awaiting |

Summary

After treated with a new HSS SHARK coating for a used HSS blade (TiAlN coating), and finished the same sharpening, which can highly improve its service time.